"GhostZ" (GhostZ)

"GhostZ" (GhostZ)

08/19/2014 at 16:10 • Filed to: None

0

0

20

20

"GhostZ" (GhostZ)

"GhostZ" (GhostZ)

08/19/2014 at 16:10 • Filed to: None |  0 0

|  20 20 |

So a recent comment on the FP about the windsor block got me thinking: How big can a Windsor Bore go?

What I'm thinking is simple: Find a cast iron 351W and bore it from 4" to 4.25". Bore spacing is 4.38" so that should leave you plenty of space. Keep the stock crank at 3.5", but go with a shorter piston and longer rod.

The result would be a 397 ci motor with a bore/stroke ratio of 1.21. As cool as it would be to have a 289 crank (for a bore/stroke ratio of 1.48 ) I would worry that you would have to rev it so high to get good power that it would become much more expensive.

Obviously the other option is to go with a Chrysler 440, which is a much bigger block but comes with a higher deck height, and a 4.32" bore from the factory. Could you use the shorter B block crank to bring it down to 3.35" to approximate a Chrysler 400 build. But this engine would be significantly heavier, more expensive to build and work on, and with a much smaller aftermarket than the Windsor.

So does anyone know if a 4.2" windsor block exists, and if it doesn't, if it is a safe bore? I've seen 4.125" all over. What's the going rate for one of these blocks these days?

crowmolly

> GhostZ

crowmolly

> GhostZ

08/19/2014 at 16:12 |

|

Well, you would have to do a lot of checking for core shift and probably hard blok.

YSI-what can brown do for you

> GhostZ

YSI-what can brown do for you

> GhostZ

08/19/2014 at 16:20 |

|

That isn't the stock spacing is it? Cause there doesn't look like much room for boring it out. . .

I don't know about bore spacing, but I know people stroke these out to some fairly bit displacement numbers. I have seen a Pantera with a 427 as well, don't know what he did with it though. Either way, totally didn't answer your question. Why not just get a stroker kit for the engine? Lots of people have done it, and you still get massive power output! Then again I don't know crap about these engines besides pushrod and it was made in Canada

MontegoMan562 is a Capri RS Owner

> GhostZ

MontegoMan562 is a Capri RS Owner

> GhostZ

08/19/2014 at 16:21 |

|

how big would you like to make my 302W at no cost to me?

GhostZ

> MontegoMan562 is a Capri RS Owner

GhostZ

> MontegoMan562 is a Capri RS Owner

08/19/2014 at 16:24 |

|

If you can cheaply and reliably bore a windsor out to 4.2" like I thought, a 333 ci motor (with some amount of raised compression) would be possible.

You'd need a stroker crank (and maybe block? I dunno) to go higher though, obviously.

lone_liberal

> GhostZ

lone_liberal

> GhostZ

08/19/2014 at 16:25 |

|

I know there are stroker kits for Windsors that get to 427ci, but I don't think those use a bore much more than 4.06 and instead use long stokes to get the displacement.

MontegoMan562 is a Capri RS Owner

> GhostZ

MontegoMan562 is a Capri RS Owner

> GhostZ

08/19/2014 at 16:34 |

|

A triple 3 motor would just be cool.

3 3's

333

I like it. Get to work!

GhostZ

> YSI-what can brown do for you

GhostZ

> YSI-what can brown do for you

08/19/2014 at 16:35 |

|

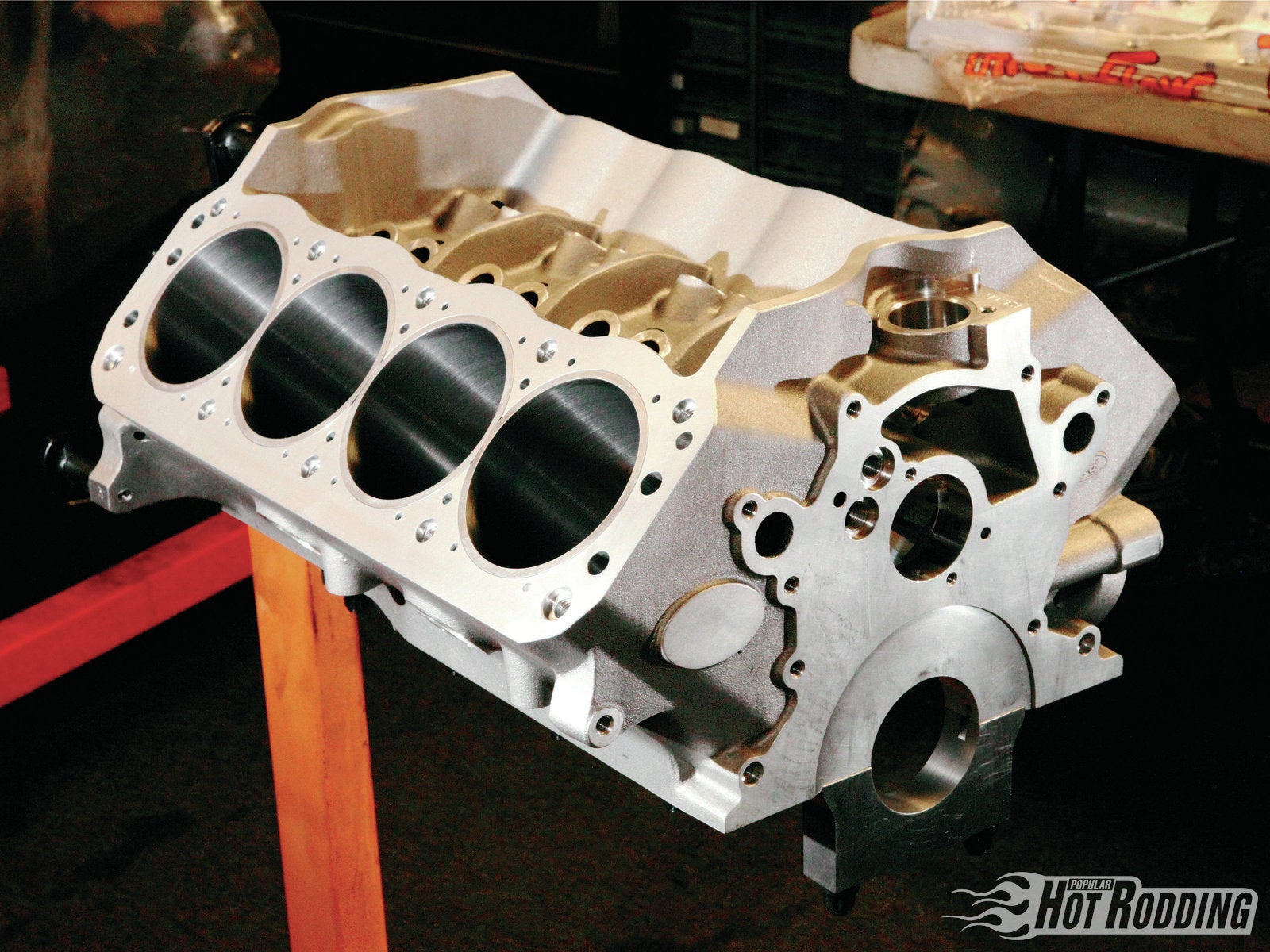

Stock spacing, but wide bores, that's a pre-bored aluminum block with sleeves I believe.

Some lazy googling shows this:

http://www.bangshift.com/assets/images/…

Which is a 4.125" bore block from Dart that they use in their 427. It seems to me that there's another .75" to go there.

A 408 stroker is really common. It's basically a 4" by 4" engine with a slight bore job. It's common because it requires as few parts to be replaced as possible to run optimally. (Stock cam still works fine).

The problem is that in a 408, by increasing the stroke you're putting a lot of stress on normal components. They're cheap and work because we have better machining capability today (just buy a rotating assembly that works) but they also won't scream to high RPMs and produce more torque than they do horsepower. I would also be worried about putting on boost, because the windsor has a short deck height . This means that if you don't want to run a very high compression ratio (or cavernous heads) you need to have short connecting rods or the pistons will be too high. A 4" stroker gives up .5" of connecting rod length and adds stroke, which is fine in a Chrysler 440 block with a massive deck height, but even the 351W blocks aren't terribly large. That's why they're so light.

This would be basically going the other route, which is keeping the stroke the same but boring it out to the limits of it's bore spacing. You'd only hit 397 instead of 408, but you'd have drastically lower piston speeds and wouldn't need a new rotating assembly, just new pistons. No need for shorter connecting rods or a carefully balanced crank to hit the same RPMs, and it should rev much higher actually.

If you do both, you end up with a 427 or larger Windsor, which are the expensive aftermarket blocks.

GhostZ

> lone_liberal

GhostZ

> lone_liberal

08/19/2014 at 16:38 |

|

Well, the 427 aftermarket blocks use a 4.125" bore. I'm wondering if you can go up to 4.2" given that the bore spacing is 4.38". That would still leave you .18" cylinder wall. If you're not using an aluminum block, would it be reliable at that large of bore?

lone_liberal

> GhostZ

lone_liberal

> GhostZ

08/19/2014 at 16:44 |

|

I see a Ford Racing 460 that maxes out their fancy aftermarket 351W block at 4.15 so I'm thinking that 4.2 would be too much for a stock block otherwise somebody would be offering it.

michael bleggi

> GhostZ

michael bleggi

> GhostZ

08/19/2014 at 17:23 |

|

aren't you a youngin? just curious but how are you so knowledgable?

GhostZ

> michael bleggi

GhostZ

> michael bleggi

08/19/2014 at 17:36 |

|

Lots and lots of research . I also spent most of my teenage years around people who were actually building windsor strokers on the cheap for not-so-legal racing.

Which is how I know what combinations, parts, etc. are needed to reach certain power and reliability requirements, but I have no practical knowledgte on what the bore limit on a windsor block would be, since I haven't actually gone and measured one myself.

So it's all economics, mathematics and theory that I know, which is more than enough to get by.

GhostZ

> michael bleggi

GhostZ

> michael bleggi

08/19/2014 at 17:39 |

|

Also, Nissan, Chryslers, and Fords are my favorites/specialities, I don't know much about obscure GM or most European brands.

YSI-what can brown do for you

> GhostZ

YSI-what can brown do for you

> GhostZ

08/19/2014 at 17:53 |

|

You said all these things, and I am just sitting here and trying to figure out what was said. Although, I felt like I learned a lot. A lot about something. . . don't know what though. One day I will be as knowledgeable as you, but by that time you will have ascended to god level.

GhostZ

> YSI-what can brown do for you

GhostZ

> YSI-what can brown do for you

08/19/2014 at 17:57 |

|

All I mean is: Stock, the engines can go up to 4.125" no problem, but can they go to 4.2" (answer: probably no. Largest block you can buy is 4.15" and is significantly modified, so a stock block probably can't hit 4.2").

Also, your post made me think of this:

Except instead of the earth, I'll be looking at a giant Watanabe rim.

YSI-what can brown do for you

> GhostZ

YSI-what can brown do for you

> GhostZ

08/19/2014 at 17:59 |

|

Well I mean, I got that. I just don't quite understand why deck heights would be good or bad for boost and so on. If you would like to explain to me what deck height is(I am assuming distance from the crank to the heads or something) and what is best for high performance situations and such, that would be fantastic!

Also, have you ever thought about sharing this info with oppo, you should totally make a post explaining this sort of stuff!

GhostZ

> YSI-what can brown do for you

GhostZ

> YSI-what can brown do for you

08/19/2014 at 18:56 |

|

Deck height is the center of the crank, to the top of the block, where the gaskets (before the heads) would be.

So on a 3" stroke motor, you have 1.5" sticking into the cylinder when the piston is at the top. Add connecting rod length, which is the length from the center of the connecting rod's bolt on one end, to the center of the bolt on the other. (not the actual length of the part, because it's the center of the rotation where force is transferred).

Then add piston height, which is the top of the piston to the center of the hole at the bottom. Here's a great chart for stock rod lengths on most US V8s: https://www.lunatipower.com/Tech/Rods/RodL…

In a Ford 302, it's a 3" stroke, 1.6" piston, and 5.09" rod lengths. That makes for a total length of 1.5 + 1.6 + 5.09 or 8.19" total. The Deck height of a 302 is 8.201". This means that the pistons, at their top, will have .011" of extra space. That's where you put on a headgasket, which gives you .03" of space, making for a total of .019" below the gasket.

Now here is where it gets interesting:

The peak RPM of a given material strength (tensile strength) can be approximated mathematically based on mean piston speeds, which is the average speed that a piston moves at a given RPM. Most modern performance engines can do 4200 ft/min reliably. Older motors like a 302 will do ~3500. This is affected by a LARGE variety of factors, which all contribute to the "strength" of the rotating assembly.

The longer your stroke, the higher your mean piston speed for a given RPM. It's a proportional trade off, a 4" stroke at 3500rpm is like a 2" stroke at 7000rpm.

But less well-known is the rod/stroke ratio. When a piston is forced upward in the cylinder, it is being pushed at an angle, forming a triangular force (up and to the right or left) on it. This is where most engine friction comes from, as the pistons are being pressed into the wall before they reach the top, and combustion is forcing the piston back into the opposite wall.

Rod/stroke ratio is important because the size of that triangle (piston, center of crank, and connection between the crank and the conrod) affects both the mean piston speed AND the safe RPM for continued lubrication. If you have a short rod/stroke ratio, that angle that it pushes the piston into the wall increases, meaning you have both more friction AND more force pushing that piston away from its intended destination. Basic trigonometry.

When we say "rod stroke" ratio, we're just talking about that angle. You want as shallow angle as possible, so you want the longest rod and the shortest stroke, to avoid those problems.

Here's how boost comes in:

Deck Height and compression ratio are intricately tied. You can reduce the compression ratio dramatically by using shorter pistons, or increase it with longer rods. You already know that higher compression ratios cause predetonation under boost. Compression ratio also has to do with the size of the heads. However, there is an optimum head shape that has to be maintained to get the most power out of combusion (has to do with explosive fronts and some thermodynamics that is beyond me).

So in a 408 stroker, you're increasing the stroke, reducing the rod/stroke ratio. You have 2 choices: 1. Run very high compression (with large volume heads) and the same stroke. I have a handy excel spreadsheet that I plugged the numbers into: on the stock rod, your piston is going to be sticking .49" out of the block. If you ran a 1.2" piston (instead of 1.6", you'll have .089" out of the block. With 71cc heads, that yields a compression ratio of 14.9. To get that ratio down to even 11, you'd need around 92cc heads. This is way out of the reasonable range (71 is the high end of aftermarket) for running boost, because you lose cylinder pressure on combustion chamber that big, creating all sorts of cylinder vacuum nastiness that messes with your valves.

Not only that, but the rod stroke ratio goes from 1.69 to 1.27. This increases the angle that you'll be pushing on the piston by a whopping 25%.

Next, there's RPM. If you want to get the most efficiency out of a turbo, you need to run the engine at higher RPMs. This is because in a properly tuned engine, the intake and exhaust will pulse in and out with the valves, so that more air is forced in when the valve opens, and air is sucked out when the exhaust valve opens. The higher the RPM, the greater this effect is amplified. In fact, some engines produce an 'effective' boost of 2-3 psi when over 8000rpm even without running turbos because of this effect.

And you're still running it on a 11:1 compression. If you want to reach 10:1 or less, you have to get an even SHORTER connecting rod.

This means on a shorter stroke motor revving higher, you'll get more overall power at the same level of boost than a longer stroke motor revving lower, despite everything else being the "same".

Increasing the bore does none of these adverse effects, and it lets you use larger cylinder heads without a problem (since the smaller size is too small for the new bore).

Now, if you use a 351W block (which has a higher deck height) not only do you have more freedom in selecting rod lengths because of the added deck height, but you can run smaller-chamber heads for the same compression ratio.

408 stroker:

Bore: 4.03"

Stroke: 4"

Conrod length, piston length: 5.09, 1.2

Deck Clearance w/ .03" gasket: .054" out of block

Head Volume: 95cc

Compression: 11:1, can't go lower without shorter rods

3800 mean piston speed at: 5700rpm

Rod/stroke ratio: 1.27

Now here's the same specs, but using a bored out 351W block instead of a stroke 302W block, utilizing that 9.5" (instead of 8.2") deck height:

387 "borer":

Bore: 4.15" (max safe bore I can find)

Stroke: 3.5" (stock)

Conrod length, piston length: 5.95, 1.6 (both stock)

Deck Clearance w/ .03" gasket: .23" inside hole

Head Volume: 58cc (standard)

Compression: 8.2:1 (much better for boost)

3800 mean piston speed at: ~6550rpm

Rod/stroke ratio: 1.69

Now do the same, but with the shorter pistons and longer rods:

Bore: 4.15" (max safe bore I can find)

Stroke: 3.5" (stock)

Conrod length, piston length: 6.4, 1.2

Deck Clearance w/ .03" gasket: .18 inside hole

Head Volume: 58cc

Compression: 9:1

3800 mean piston speed at: ~6550rpm

Rod/stroke ratio:

1.83

or nearly 43% better than the 408 stroker.

BiTurbo228 - Dr Frankenstein of Spitfires

> GhostZ

BiTurbo228 - Dr Frankenstein of Spitfires

> GhostZ

08/20/2014 at 06:51 |

|

Hmmm, so saying that you can reliably go to a 4.25" bore, what would be the absolute limit for a big-bore and stroked Windsor?

GhostZ

> BiTurbo228 - Dr Frankenstein of Spitfires

GhostZ

> BiTurbo228 - Dr Frankenstein of Spitfires

08/20/2014 at 07:17 |

|

Someone else commented for me elsewhere, but the absolute bore limit is actually closer to 4.15, and that's on an aftermarket block. Stroke is probably somewhere around 4.1 - 4.2, so let's assume a square block at 4.15 and 4.15. That's a 449, or 7.4l engine that weighs the same as a Ford 351, not bad at all.

BiTurbo228 - Dr Frankenstein of Spitfires

> GhostZ

BiTurbo228 - Dr Frankenstein of Spitfires

> GhostZ

08/20/2014 at 07:25 |

|

Bloody hell that's not bad :)

GhostZ

> BiTurbo228 - Dr Frankenstein of Spitfires

GhostZ

> BiTurbo228 - Dr Frankenstein of Spitfires

08/20/2014 at 10:53 |

|

You're telling me. Given that there's about 10 different aftermarket blocks ranging from a few thousand to V6 mustang price ranges, I had no idea that the windsor engine had so much potential.